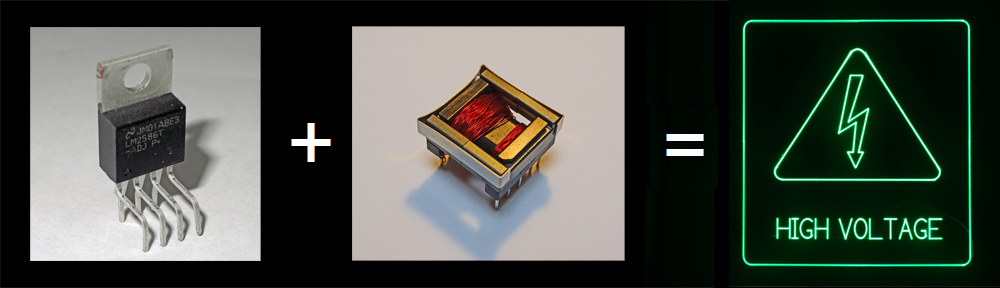

Winding your own HV Transformer

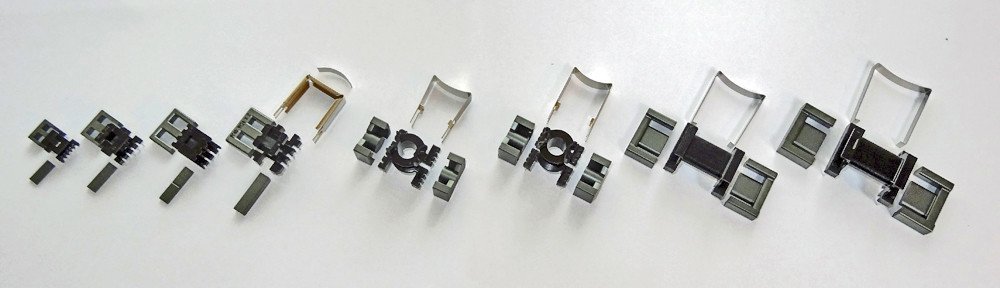

In Transformer Corner Part 3, I looked at how to choose materials for a custom HV transformer. One way was to pull stuff from the junk-box – I did this in my early Prototype. The much, much better way was to use an off-the-shelf core with documented specs.

Let’s look at winding up the transformer. It’s amazingly easy to get a workable result!