For Christmas, @oscillokid gave your humble senior Oscilloclock engineer a book: Why do Buses Come in Threes? It’s a playful tome, with surprising facts about how mathematics plays a part in nature and society.

From three-leaf rules in plants, to the musical triad, to triple bird call repetitions, to The Three Body Problem — this magic number is everywhere.

And it’s no coincidence that Oscilloclocks also Come in Threes!

Do Oscilloclocks really come in Threes?

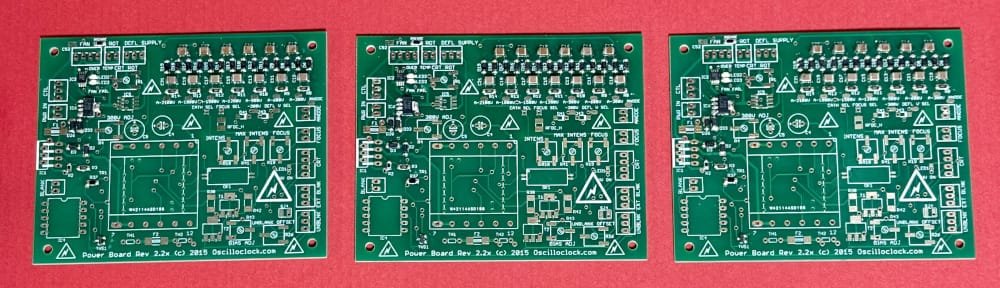

Yes! But to be more precise, it’s the Oscilloclock printed circuit boards that come three at a time. Here you can see three boards being assembled:

Why in Threes?

Well, every component of your Oscilloclock is manually picked from a bin, manually placed on the board, and manually hand-soldered.

In a standard Oscilloclock model such as the Model 1 or the Exo, there are more than 300 individual parts!

Picking, placing, and soldering just one board is onerous. Two boards? Tedious! And in such finite physical space, four boards is futile. Three wins!

Wait – do you even procure in Threes?

Yes. We order parts from reliable distributors in very small quantities. The magic formula is a small multiple of 3, plus an extra one or two to fit minimum quantity restrictions and to cover parts attrition. The duly received parts are then manually unpacked and manually placed into the bins.

By the way, parts attrition is the phenomenon where parts are wasted: misplaced, incorrectly mounted, or broken during assembly. At the Oscilloclock lab, we are proud to have an average attrition rate of less than 2%!

Why procure parts in such tiny quantities?

Ordering in large quantities is cheaper.

But — we want the latest and greatest for our Oscilloclock owners! Even for the exact same component type and the same manufacturer, fresh lots may perform better and/or last longer than older lots, thanks to advances in design or manufacturing processes.

Additionally, Oscilloclock circuit designs are constantly evolving. We prefer to adapt to newer component types regularly (with a few exceptions).

Having a huge backlog of old stock would encourage us to stagnate. No way!

Why not “mass produce”?

Simple. Our motto is ‘Hand Crafted Scope Clocks’! This means an artisan design and assembly process, right down to the soldering.

This fits with the Made In Japan mantra and the country’s ものづくり (monozukuri) culture. In an era where board factories are exclusively located overseas, embracing hand assembly helps keeps things local.

Lastly, factory procurement and assembly is more costly in Threes. And we don’t want to increase quantities, as we constantly evolve the designs.

But isn’t hand assembly a lot of effort?

Yes, it is. Procuring the parts and assembling the boards takes hours. But it’s worth it to our Oscilloclock engineers!

- The sheer joy of hand-crafting something for someone else.

- The control over aesthetics such as precise component placement.

- A dopamine rush as anticipation grows to the climax of final testing!

We DO use factory assembly sometimes…

That said, we aren’t silly! We DO use factory assembly for bespoke work where miniaturization or performance demands outweigh the joys and aesthetics of hand assembly.

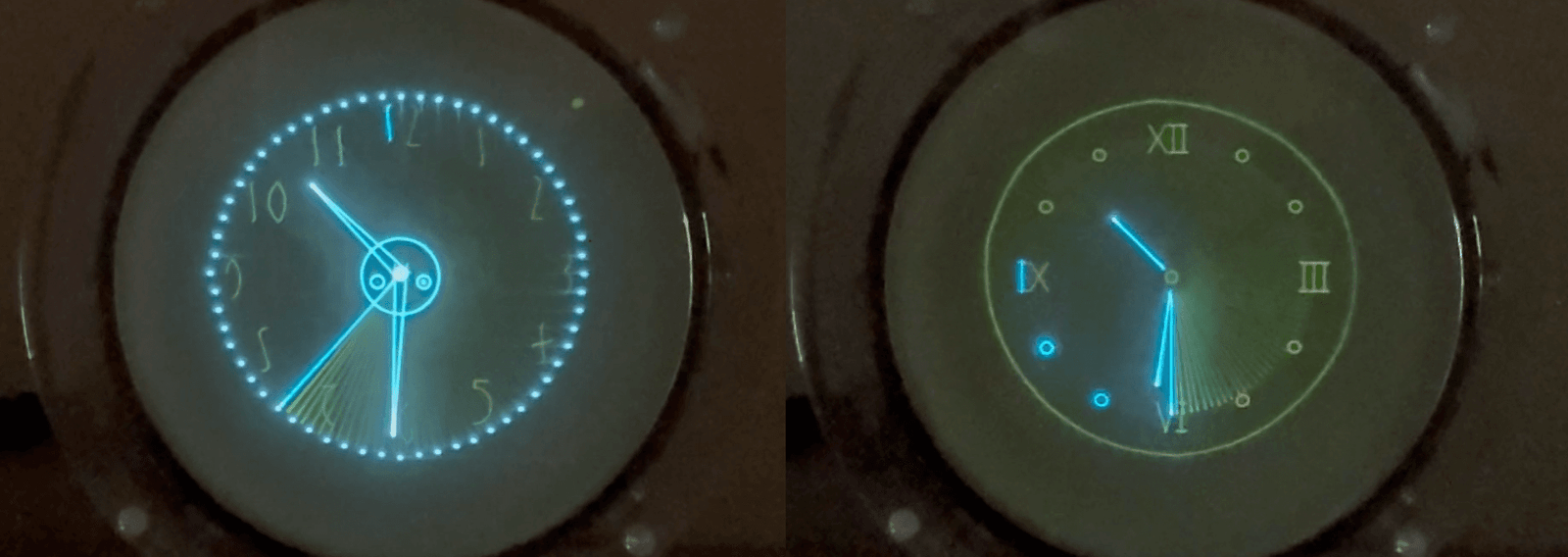

For example, the heavily specialized Oscilloclock Core Duo System below is designed to drive dual-gun cathode-ray tubes in a very small form factor. At this level of miniaturization, factory assembly is a given.

What else is “Hand-Crafted”?

Acrylic. We use cast acrylic (not extruded). The raw material is manufactured in Japan, and then machined locally, by hand, and to order.

Fan mounts. We’ve shown this before, but we can’t help but show it again!

Cables and Harnesses. Hand- everything! See our earlier write-up.

The Printed circuit boards themselves? No! Sorry to disappoint you, poor reader, but the last time we etched PCBs was for the Prototype. With all the messy chemicals and finicky alignment required for double-sided boards, we draw the line here!

They say, “Good luck comes in threes”. We think so. And our patrons must think so, for several of them have commissioned three (or more) devices!

Do you want to explore possibilities? Reach out with an idea. Or three!