We love to re-use, upcycle, recycle, restore, re-invigorate!

We scour the planet, rescuing unique-looking cathode-ray tube based devices from certain destruction. We have oodles of oscilloscopes, spectrum analyzers, capacitor testers, audio monitors, medical instruments, television broadcast equipment, engine analyzers, and so much more!

Check out these newly arrived devices, just waiting to become Oscilloclocks:

Fukuda CS-1A Cardio-Scope

A bed-side heart rate monitor, used in hospitals of yester-yore.

By default fitted with a long-persistence 5″ CRT and amber filter.

A colourful addition to any bedroom!

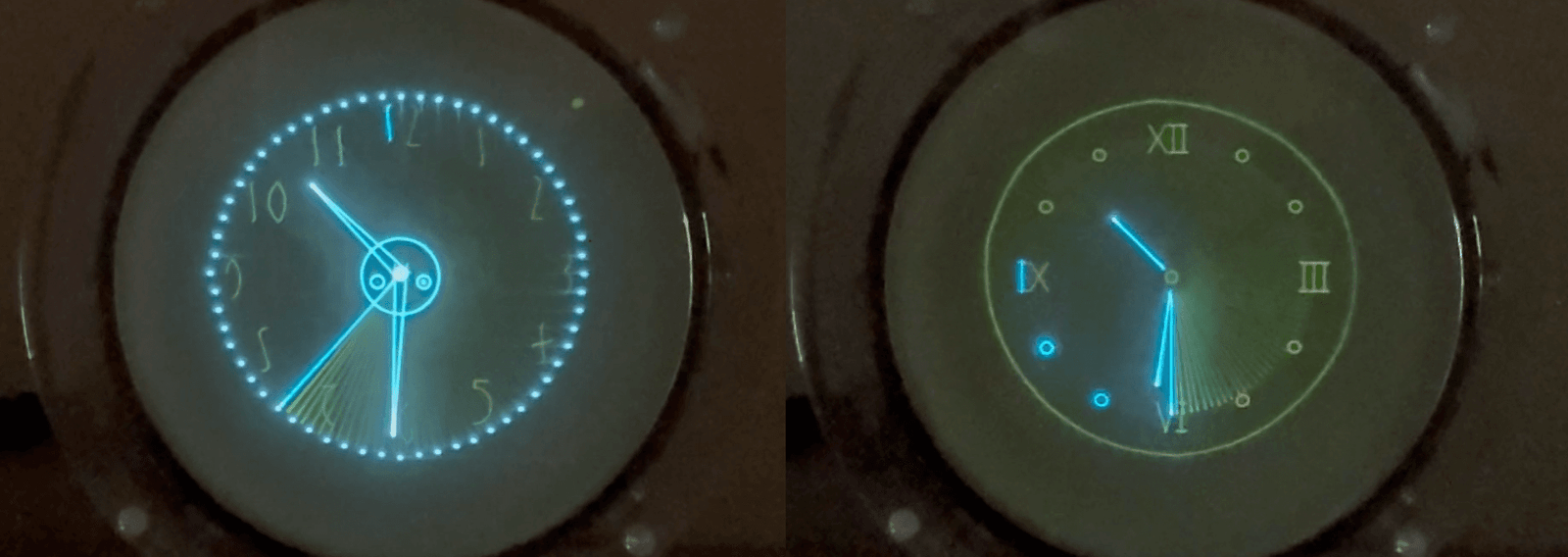

HP 8414A Polar Display

This early 1970’s Hewlett Packard green-screened device will take your living room straight back to the Space Age! The display is rack-mounted by default, serving up a full NASA look-and-feel.

And removed from the rack, the 8414A is as cute as a button! It’s the perfect size for your desk, coffee table, or display case.

And for the truly serious NASA enthusiast, we might rack-mount the display next to a blue-phosphor HP 8412A Phase-Magnitude display. A dual-display visual virtuoso!

Cleaning, restoration, and modifications

These devices are original and deliciously dirty! We’ll do our best to clean, polish, wax, and otherwise restore every surface as much as practical.

If you really want, we’ll re-paint, re-plate, re-finish, or re-anything – to get you the right look & feel.

We can modify with cast acrylic side panels, custom-turned wooden knobs, or brass bezels. We can do anything, in theory. Warning: diamond-studded escutcheons do tend to be rather expensive.

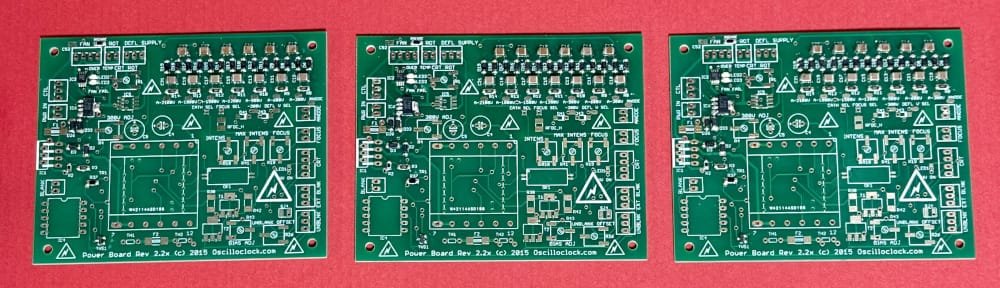

Minimal invasion vs. Full conversion

Our default recommendation is to bypass all the existing circuitry with a full set of Oscilloclock boards that drive the CRT directly. This ‘full conversion’ approach gives best performance, maximum reliability, and allows us to offer a full 3-year warranty on all components (except the CRT).

But some devices are, miraculously, in partial or even full working condition when discovered! If the device can be electrically restored, we can apply a ‘minimal invasion, maximum re-use’ policy – keeping the existing circuitry alive, and installing only what’s needed to control the display. While reliability and performance suffer, this allows us to keep the original controls mostly functional, for the ultimate in twiddling pleasure!

Stripping and weight reduction

Many vintage devices are heavy! For owners who are less fastidious about maintaining internal originality, we can strip out unnecessary components and circuitry to lighten up the final product significantly.

Some owners take this option, but additionally request that we retain every wire, board, and screw in a separate box for them to admire. We applaud their fascination in their device’s history and its engineering culture!

If you like the look of these new-found beauties, let us know. If you don’t, let us know. If you have your own beloved device to convert, let us know.

Heck, just let us know!